| 特点 |

● 采用RS485 Modbus-RTU总线协议,最多可挂载64个驱动器

● 内置单轴控制器和驱动器功能,支持位置控制、速度控制和多段位置控制

● 设有16档等角度恒力矩细分,最高分辨率52100步/转

● 3路光电隔离可编程高速差分输入接口,1路光电隔离输出接口

● 采用独特的4线控制电路,有效的降低了噪音,增加了转动平稳性

● 最高反应频率可达200KHz

● 步进脉冲停止超过100ms时,线圈电流自动减半,减小了步进电机过热

● 双极恒流斩波方式,使得相同的步进电机可以输出更大的速度和功率

● 驱动器电流:0.1A~5A

● 单电源输入,电压范围: DC24~50V(最佳输入电压 DC48V)

● 信号原电压范围: DC3.3~28V(任意输入,无需外加限流电阻)

● 出错保护:①供电电压低 ②供电电压高 ③相位开路 ④相位过流 ⑤编码器故障

● 外形尺寸:117×75.7×40.6(mm),净重量:0.27kg

| 概述 |

SEB2M55-R RS485 Modbus-RTU总线型闭环步进驱动器是在闭环步进驱动器基础上增加了总线通讯及单轴控制器功能。

该总线闭环驱动器在功能上可以完全替代传统脉冲方向控制的闭环驱动器,驱动器内置总线通讯功能,采用Modbus-RTU总线通讯,用户可以同时控制32台驱动器,同时,改总线闭环驱动器具有丰富的输入/输出接口,用于完成位置控制、速度控制、回原点等单轴运动控制功能,与传统的闭环驱动器相比,这款总线闭环驱动器特别适合多台数、远距离、强干扰环境的场合应用,总线闭环驱动器输入电压DC24V~50V( 最佳输入电压 DC48V),采用单电源供电,适配外径56mm~60mm、相电流在5A以下二相混合式闭环步进电机。

总线闭环驱动器内部采用基于负载的电流控制技术,可有效延长闭环步进电机使用寿命与降低发热,驱动器内置有位置到达信号和报警信号输出,方便控制器进行监测和控制。

| 应用领域 |

木工雕刻机、激光雕刻机、打标机、贴标机、固晶机、焊线机、UV打印机、3D打印机、喷绘机、绘图仪、绣花机、点胶机、灌胶机、焊锡机、BGA返修台、贴合机、贴片机、热压机、背光源贴膜机、涂装机、往复机、端子机、剥线机、绕线机、锡膏印刷机、PCB钻孔机、V-CUT机、打靶机、FPC补强机、涂布机、叠片机、IC分选机、IC烧录机、编带机、医疗设备、非标设备、XYZ测量仪、连接器组装机、SMT周边设备等

| 通讯地址设定表 |

地址 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

SW1 | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF |

SW2 | ON | ON | OFF | OFF | ON | ON | OFF | OFF | ON | ON | OFF | OFF | ON | ON | OFF | OFF |

SW3 | ON | ON | ON | ON | OFF | OFF | OFF | OFF | ON | ON | ON | ON | OFF | OFF | OFF | OFF |

SW4 | ON | ON | ON | ON | ON | ON | ON | ON | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF |

SW5 | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON |

SW6 | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON |

地址 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 |

SW1 | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF |

SW2 | ON | ON | OFF | OFF | ON | ON | OFF | OFF | ON | ON | OFF | OFF | ON | ON | OFF | OFF |

SW3 | ON | ON | ON | ON | OFF | OFF | OFF | OFF | ON | ON | ON | ON | OFF | OFF | OFF | OFF |

SW4 | ON | ON | ON | ON | ON | ON | ON | ON | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF |

SW5 | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF |

SW6 | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON |

地址 | 33 | 34 | 35 | 36 | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 | 46 | 47 | 48 |

SW1 | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF |

SW2 | ON | ON | OFF | OFF | ON | ON | OFF | OFF | ON | ON | OFF | OFF | ON | ON | OFF | OFF |

SW3 | ON | ON | ON | ON | OFF | OFF | OFF | OFF | ON | ON | ON | ON | OFF | OFF | OFF | OFF |

SW4 | ON | ON | ON | ON | ON | ON | ON | ON | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF |

SW5 | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON |

SW6 | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF |

地址 | 49 | 50 | 51 | 52 | 53 | 54 | 55 | 56 | 57 | 58 | 59 | 60 | 61 | 62 | 63 | 64 |

SW1 | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF |

SW2 | ON | ON | OFF | OFF | ON | ON | OFF | OFF | ON | ON | OFF | OFF | ON | ON | OFF | OFF |

SW3 | ON | ON | ON | ON | OFF | OFF | OFF | OFF | ON | ON | ON | ON | OFF | OFF | OFF | OFF |

SW4 | ON | ON | ON | ON | ON | ON | ON | ON | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF |

SW5 | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF |

SW6 | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF |

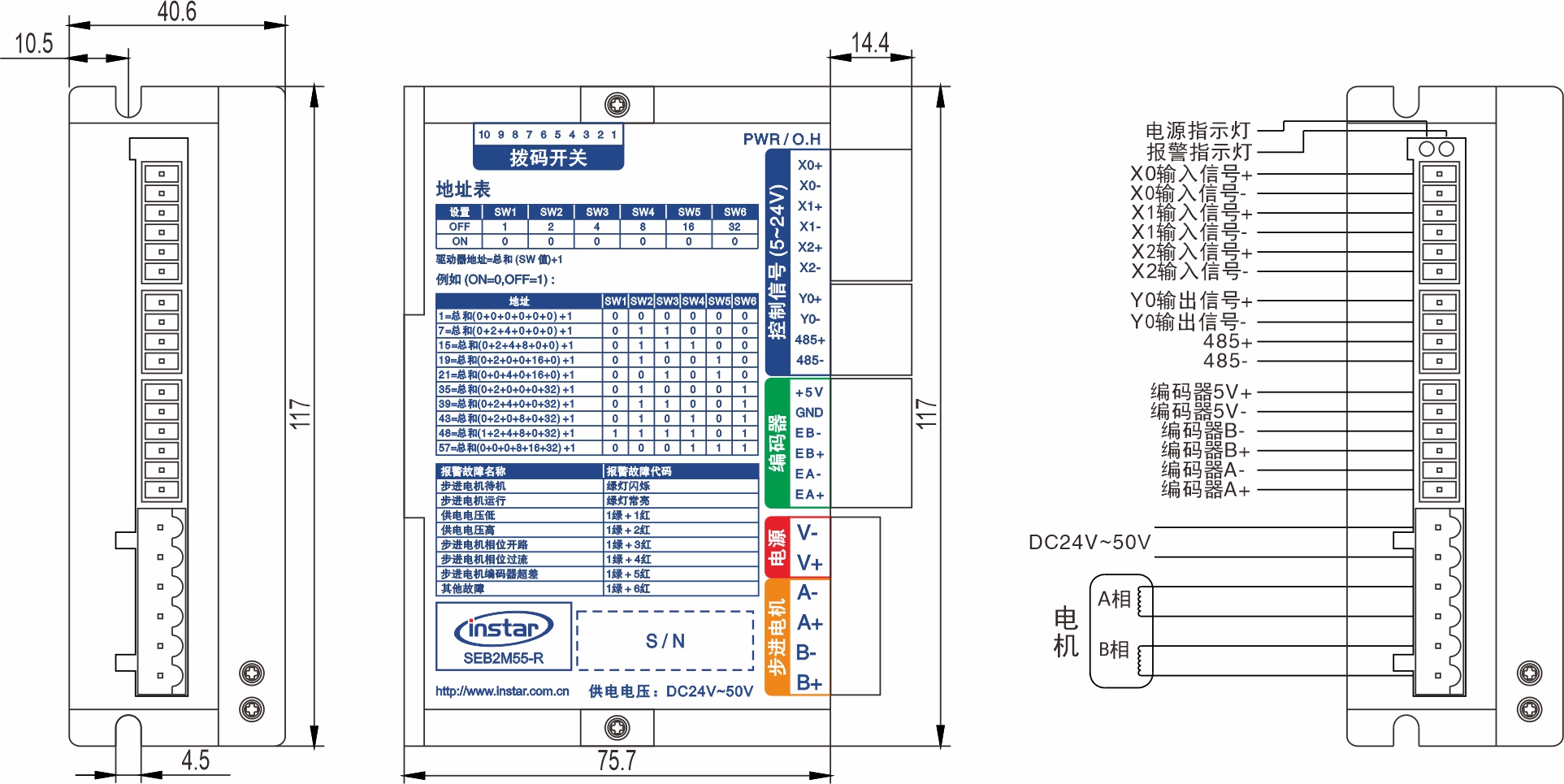

| 外形尺寸图 |

| 引脚功能说明 |

标记符号 | 功能 | 注 释 |

POWER | 电源指示灯 | 通电时,指示灯闪烁。 |

O.H | 故障指示灯 | 驱动器电流过高、相位开路、供电电压高、电压低、位置超差时红色指示灯闪烁。 |

X0+ | 输入信号光电隔离正端 | 输入信号,输入电压范围+3.8V~+28,最大电流10mA,用户可以通过总线配置相应端口功能。 |

X0- | 输入信号光电隔离负端 | |

X1+ | 输入信号光电隔离正端 | |

X1- | 输入信号光电隔离负端 | |

X2+ | 输入信号光电隔离正端 | |

X2- | 输入信号光电隔离负端 | |

Y0+ | 输出信号光电隔离正端 | 输出信号,输出电压范围+3.3V~+28V,最大电流15mA,用户可以通过总线配置相应端口功能。 |

Y0- | 输出信号光电隔离负端 | |

485+ | RS-485+ | 485总线数据正端 |

485- | RS-485- | 485总线数据负端 |

+V | 电源正极 | DC24~50V ( 最佳输入电压DC48V ) |

-V | 电源负极 | |

+A、-A | 步进电机接线 | 请参照各步进电机接线图。 |

+B、-B |

| 报警功能 |

● 当 1 绿 1 红 闪烁时,表示闭环驱动器供电电压低;解决方法:检查闭环驱动器供电电压是否过低;

● 当 1 绿 2 红 闪烁时,表示闭环驱动器供电电压高;解决方法:检查闭环驱动器供电电压是否过高;

● 当 1 绿 3 红 闪烁时,表示闭环步进电机相位开路;解决方法:检查闭环步进电机接线是否错误;

● 当 1 绿 4 红 闪烁时,表示闭环步进电机相位过流;解决方法:检查闭环驱动器MOS管是否损坏或闭环步进电机是否损坏;

● 当 1 绿 5 红 闪烁时,表示闭环步进电机编码器故障;解决方法:检查闭环步进电机编码器是否接线正确和是否损坏;

● 当 1 绿 6 红 闪烁时,表示闭环步进电机编码器反馈位置超差;解决方法:检查闭环步进电机是否丢步;

● 当 1 绿 7 红 闪烁时,表示闭环驱动器其他故障;解决方法:寄回厂家检测;

以上报警功能启动时,步进电机失去自锁能力,若要回复正常工作,需要确认以上故障消除,然后重新上电,绿色电源指示灯常亮,驱动器回复正常。

▲ 注意:由于驱动器不具备电源正负极反接保护功能,因此上电前请再次确认电源正负极接线是否正确,否则电源正负极接反将导致烧坏驱动器中的保险管。

English

English 繁體

繁體